Configuration-dependency of Stiffness at the tool-tip

Our research has studied the effect of the cutting forces at the tooltip of the parallel kinematic mechanism (PKM). It was found that the damping ratios of the frequency response function (FRF) at the tool-tip were configuration-dependent. This, in turn, makes the peak amplitude of the displacement response at the tool-tip configuration-dependent as well.

Redundant Parallel Kinematic Mechanisms

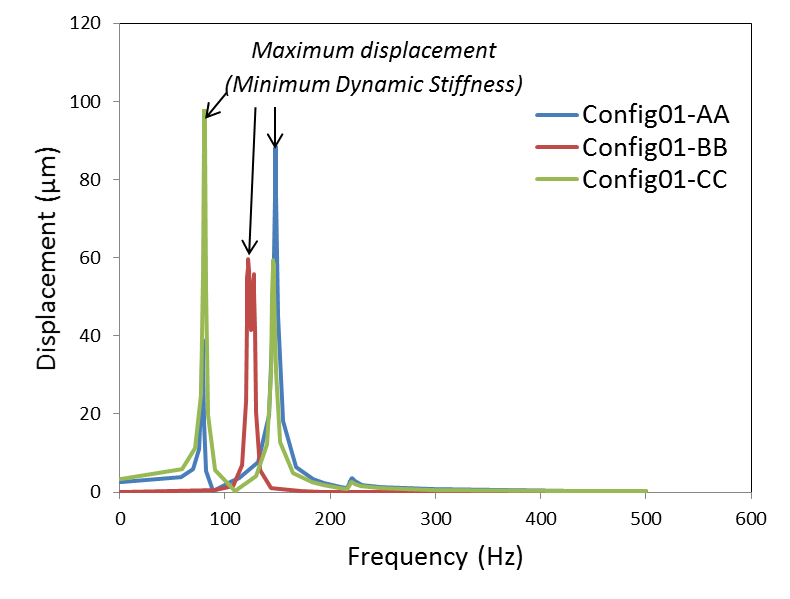

Since stiffness at the tool-tip is configuration-dependent, a method is needed to select the most stiff configuration. Figure 1 shows three redundant configurations of a PKM and Figure 2 shows the corresponding displacement at the tool-tip FRF.

Figure 1-AA, BB, CC. Three Redundant Configurations For A Given Platform Pose

Figure 2. Displacement FRF of the Three Redundant Configurations

Artificial Neural Network (ANN) based Stiffness Emulator

There exist different methods to determine the stiffness of a PKM, such as Final Element Analysis (FEA) or analytical models. However, they are either too slow for on-line operation or too complex and require extensive experimental validation to be reliable.

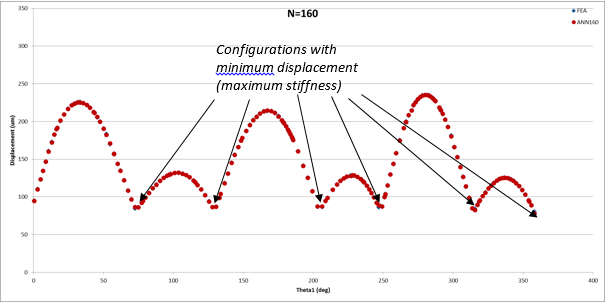

Our contribution includes a neural network based emulator which predicts the stiffness of a PKM configuration and can be used to optimize the stiffness during on-line operations. Figure 3 shows the maximum displacement of the tool-tip for redundant configurations using the ANN-emulator predictions.

Figure 3. ANN-based Emulator Stiffness Prediction