The focus of our research has been two fold:

- (i) the development of an efficient supervisory-control system based on a formal Discrete-Event-System (DES) theory, and

- (ii) the implementation of this system using programmable logic controller (PLC) technology.

The design of a supervisory controller entails the formulation of control laws and the synthesis of supervisors. The laws specify how the supervisor is to react to the behaviour of the manufacturing system, the goal being to have some production specifications satisfied within the standing control enforcement constraints. Petri nets, real-time temporal logic, timed transition models, and controlled automata have been used for this purpose.

Our research focuses on the application and development of a DES theory based supervisor applied to flexible manufacturing systems. DESs have the desirable feature that their behaviour may be proven and verified correct before implementation, using the tools developed within the theory. However, the control of even moderately complex systems can easily require an immensely large DES strategy. Attempting to cope with this problem, a hybrid supervisory controller, that splits operations between a DES-based supervisory controller and another mechanism, was developed. The alternate mechanism asserts control whenever events diverge from the states of the DES supervisory controller.

When using flexible manufacturing workcells, however, parts can be produced in many possible orders of operations and choices of different machines. This allows us to produce a variety of (customized) products with varying demand. Attempting to cope with these issues, Extended-Moore Automata(EMA) is being used to automatically synthesize control strategies that allow part-routing flexibility and resource sharing. The obtained supervisors are thereafter translated into ladder logic and downloaded into a PLC for execution.

The result of this research has generated a Supervisory Control Software. The proposed approach uses a GUI where the user is asked simple questions regarding the processing routes of the part types to be manufactured and the constraints to be imposed on the system. The information is then automatically transformed into a set of EMA models used for the efficient synthesis of formal supervisors. The control strategy is, thereafter, automatically translated into ladder logic and downloaded into a PLC for execution. The details on how cell devices are to be connected to the I/O ports of the corresponding PLC are automatically determined by the software, which is also used to monitor the workcell.

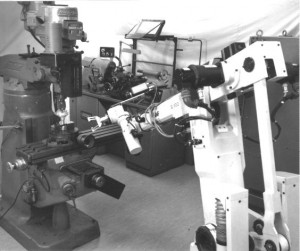

Currently EMA-based supervisors are being implemented on the Allen Bradley Series 5/11 PLCs used to control a robotic manufacturing workcell within the CIMlab.

Another issue being considered within this project is the control of Flexible-Manufacturing Systems (FMSs) which may comprise a number of workcells where production resources are shared among the cells for a variety of practical reasons.